About Us

CEO Message

“Welcome to ROTOTECH, your trusted partner in providing quality mechanical and electrical parts for Hydro Power Plants. We take pride in offering exceptional service to our clients, and our team of experts is dedicated to delivering the best solutions to meet your needs.

Our mission at ROTOTECH is to provide our customers with reliable, innovative, and cost-effective solutions that enable them to achieve their business goals. We understand the importance of efficiency, productivity, and safety in the power generation industry, and we strive to provide products and services that meet these requirements.

At ROTOTECH, we are committed to continuous improvement and innovation. We constantly invest in research and development to ensure that our products are of the highest quality and meet the latest industry standards. We also work closely with our customers to understand their specific needs and challenges, and to provide customized solutions that meet their unique requirements.

We believe that our success is based on the trust and loyalty of our customers. That’s why we are committed to building long-term relationships with our clients and providing exceptional customer service. We are proud to have served the Hydro Power Plants for many years, and we look forward to continuing to support your business in the years to come.

Thank you for choosing ROTOTECH as your partner in the Hydro Power generation industry. We look forward to working with you.”

MUGHAL ENGINEERING COMPANY (1948)

The History of the Mughal Engineering Company goes back to 1948 when it was established in Peshawar as a small workshop to cater to the need of this small town in the North West of Pakistan.

A 1917 Drummond foot pedal-driven lathe machine was the first step towards making up the first screw compressor in Pakistan. It started by repairing electric fans. With the introduction of the small engineering industry, the company went into repairing industrial machines. During this time it also remains engaged in the refurbishment of automobile engines. The experience in this field led to the repair of ammonia compressors installed in the upcoming ice factories of the region. Gradually the industrial base of the region expanded and industries such as sugar, paper, textile, bulb, glass, and safety match Factories and pharmaceuticals were set up. With these industries, the demand for air compressors increased. This forced the management to train its staff in this field and acquire relevant machines to better cater to the industry. With the high prices of gasoline fuel, a new wave of CNG refueling stations emerged in the region making Pakistan the third biggest user of CNG in the world. Here, once again Mughal Engineering Company came forward in providing services to this sector. Along with providing services for the CNG, Ammonia, reciprocating, and rotary-type air compressors, Mughal Engineering Company worked on making its own compressors.

COMPMUGHAL ENGINEERING (PVT) LTD. (2004)

The Company decided to focus on the manufacturing of Air compressors. As the demand of air increased in the industry, piston type compressors with its noise, high running and maintenance cost and low quality of air, were unable to cope with the demand. As the demand of screw compressor increases Mughal Engineering Company foresees itself to fill a vacuum created due to the high cost of imported screw compressors. In 2004 the management of Mughal Engineering Company established a new company by the name of Comp Mughal Engineering (PVT) Ltd and gave it the task of developing screw compressors, refrigerated dryers and line filters. After tedious work of many months the data was collected from users of screw compressors and problems studied that the industry was facing due to the hot weather and dust of our region.

The CME designed and redesign many times to remove any shortcomings. By July 2005 the design and parts were finalized. CME contacted the best part manufacturers for screw compressors components of the world and finally selected 13 most prestigious companies.

The journey that started in 1948 has reached to a success full turn in 2006 by the completion of first ever proudly “MADE IN PAKISTAN” screw compressor under the brand name of ROTOAIR. In 2007 the group enters in to the supply of electrical and mechanical equipment for the rehabilitation of different Hydel Power Plants.

ROTOTECH (2019)

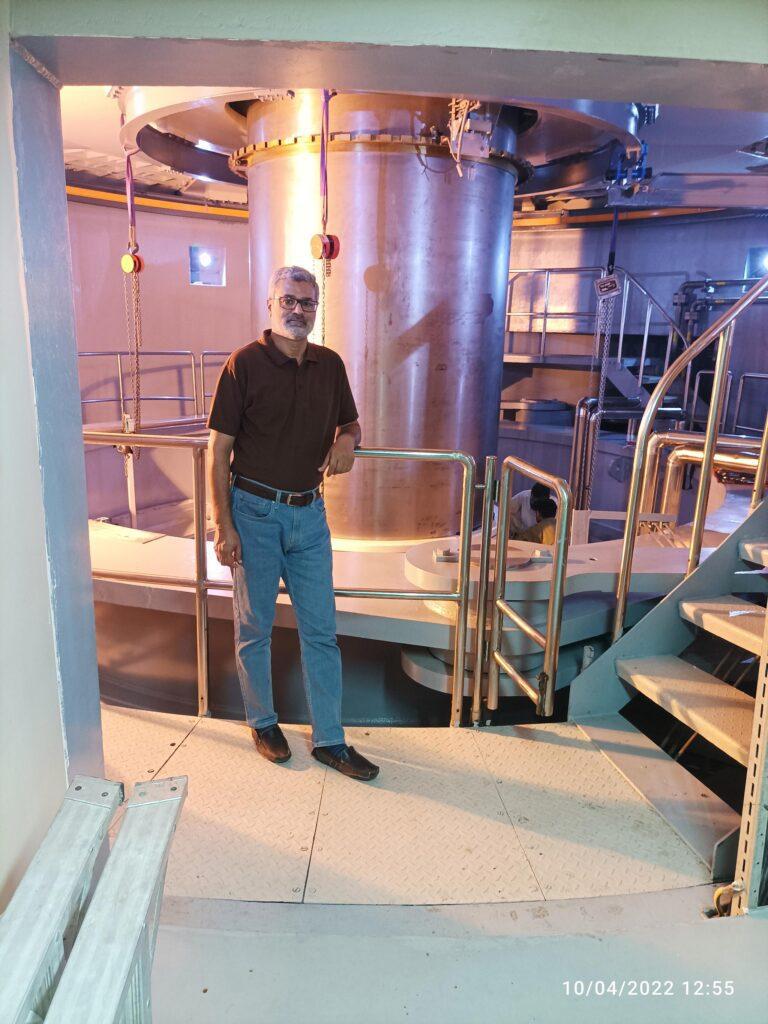

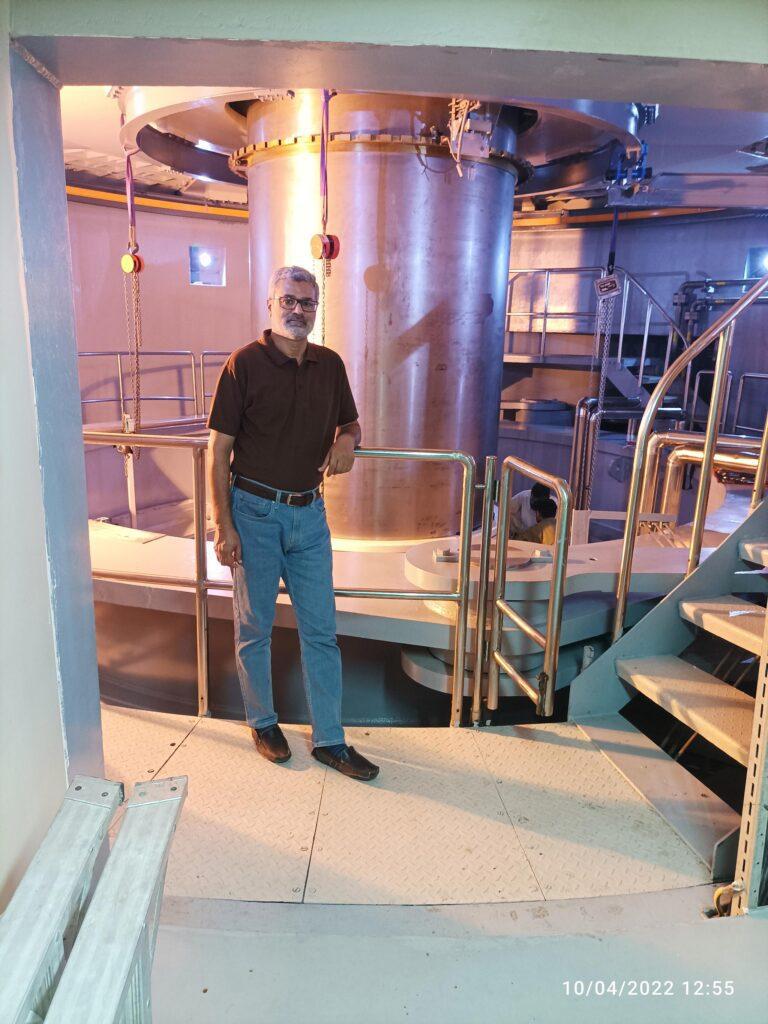

In order to meet the technical needs and equipment requirements of various power plants, with a specific focus on Hydro Power facilities, a new company was established by the group in 2019. ROTOTECH serves as the technical service and equipment provider for Hydro Power plant planning, construction, and rehabilitation. The owner and managing engineer possess over 35 years of mechanical engineering experience, with particular expertise in Hydro Power technology, enabling the company to offer a wide range of technical services. Having worked on technical projects at one of the world’s largest Hydro Power plants for numerous years, ROTOTECH excels in consulting, engineering, as well as project execution for small and large power plants, including associated auxiliary and power systems. In addition, ROTOTECH is involved in indenting projects and represents principals in international tenders initiated by government organizations, as well as public and private sectors in the country.